Commercial Hydraulic Test Bench / Stand / Console / Station

Aircraft Pumps Motors Hydraulic Test Equipment

Hydraulics International, Inc., Chatsworth, Calif., is being awarded a $22,348,042 fixed-price, indefinite-delivery/indefinite-quantity contract for the A/F27T-12 hydraulic component test stand. This contract provides for the procurement of three pilot production units of the main hydraulic console, one pilot production of the pump and motor test console, one pilot production hydraulic fluid cooling system vapor cycle, one pilot production hydraulic fluid cooling system non-vapor cycle and the associated testing, technical and logistics data, and training. Work will be performed in Chatsworth, Calif., and is expected to be completed in August 2018. Contract funds will not expire at the end of the current fiscal year. This contract was competitively procured under an electronic request for proposals as a small business set-aside; two offers were received. The Naval Air Warfare Center Aircraft Division, Lakehurst, N.J., is the contracting activity (N68335-12-D-0023). Date: August 07, 2012 US Department of Defense

(http://www.fbodaily.com/archive/2012/08-August/10-Aug-2012/FBO-02831090.htm)

(http://www.veteranstoday.com/2012/08/07/u-s-department-of-defense-contract-awards-148/)

UNIVERSAL AIRCRAFT COMPONENT TEST STAND for Jumbo Jets including next generation Jumbo, Boeing B787, A380, Airbus A350 etc.

and

Hydraulic Components fitted on both Military Aircraft & Helicopter.

A/F27T-12 replaces A/F27T-10

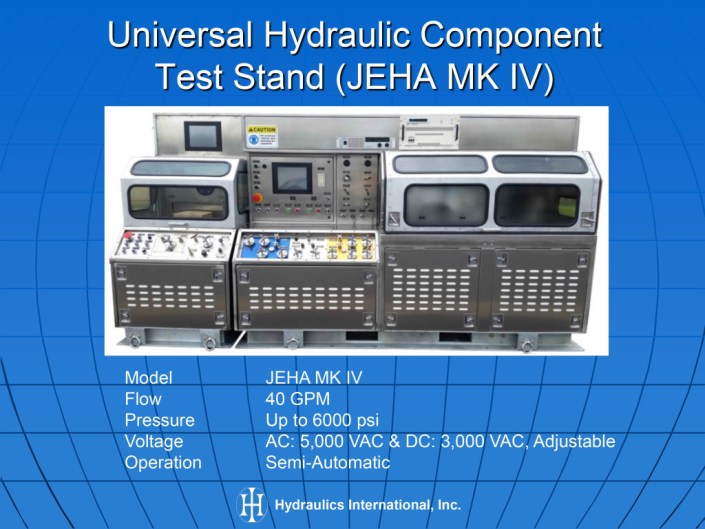

The model JEHA MARK IV or HCT-12 (A/F27T-12) is newly designed to perform all functional and operational tests of new generation commercial aircraft hydraulic and pneumatic components including (and not limited to) actuators and control valves, from both large and mid-size body aircrafts. Optional P&MTC (Pump and Motor Test Console) provides capability of testing pump and motor and can be added to JEHA MARK IV or HCT-12 (A/F27T-12) at any time if required to expand the testing capability.

Hydraulic Test Equipment, Aircraft Hydraulic Test Equipment, Hydraulic Equipment Testing, Aircraft Hydraulic Equipment Testing, Hydraulic Test System, Aircraft Hydraulic Test System, Hydraulic Test Bench, Aircraft Hydraulic Test Bench, Hydraulic Test Stand, Aircraft Hydraulic Test Bench, Hydraulic Components Test Equipment, Aircraft Hydraulic Components Test Equipment, Hydraulic Components Testing & Aircraft Hydraulic Components Testing.

Military Hydraulic Test Bench / Stand / Console / Station

*

B787, A350 & A380 Hydraulic Test Stand / Cart / Rig

![]()

![]()

![]()

PORTABLE HYDRAULIC TEST STANDS OR TEST RIGS (Large to Narrow Body Aircraft)

![]()

(Electric Motor Driven)

![]()

(Diesel Engine Driven)

*

Portable Hydraulic Test Stands (Dual System) which allow servicing and testing of all large and mid size body aircraft – such as MD-11, Boeing B787, B777, B767, B747, L1011, DC10, AIRBUS A300, A310, A320, A330, A340, A350, A380 & A400M or as long as the capacity of the hydraulic system is within the range of required test stand flow & pressure.

Commercial Aircraft Hydraulic Test Equipment (Commercial Airlines)

Military Aircraft Hydraulic Test Equipment (Air Force)

2011©Copyright HII Group. All Rights Reserved